Two Approaches to Change Management. Featuring a case example of corporate re-alignment.

Observe Change Management Models at Work: Kotters’ 8 Steps and the ADKAR Model of Change Management. Meanwhile, one fictitious company takes on the challenge of organizational change – is it too late?

SECTION 1:

An Exploration of Two Popular Approaches to Change Management

- Part A: The ADKAR Model for Change Management

- Part B: Kotter’s 8-Step Model for Change

SECTION 2:

Case Example, “Agri-RBA’s Corporate Alignment Challenge.”

- Observe Two Change Management Models at Work.

- Kotters’ 8 Steps and the ADKAR Model of Change Management.

- “Agri-RBA” takes on the challenge of organizational change.

SECTION 1:

This section includes a five minute explanation of two different change management models.

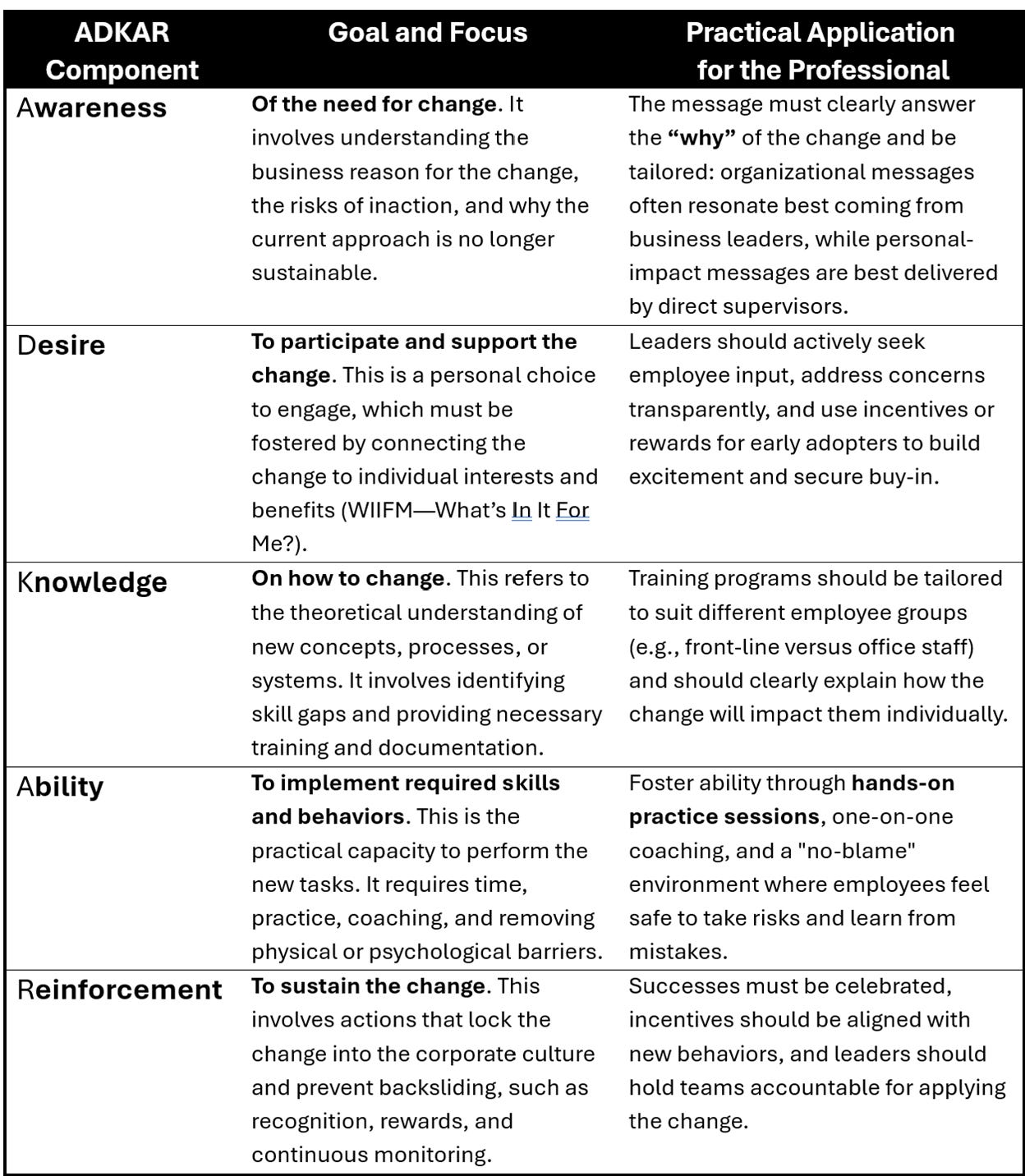

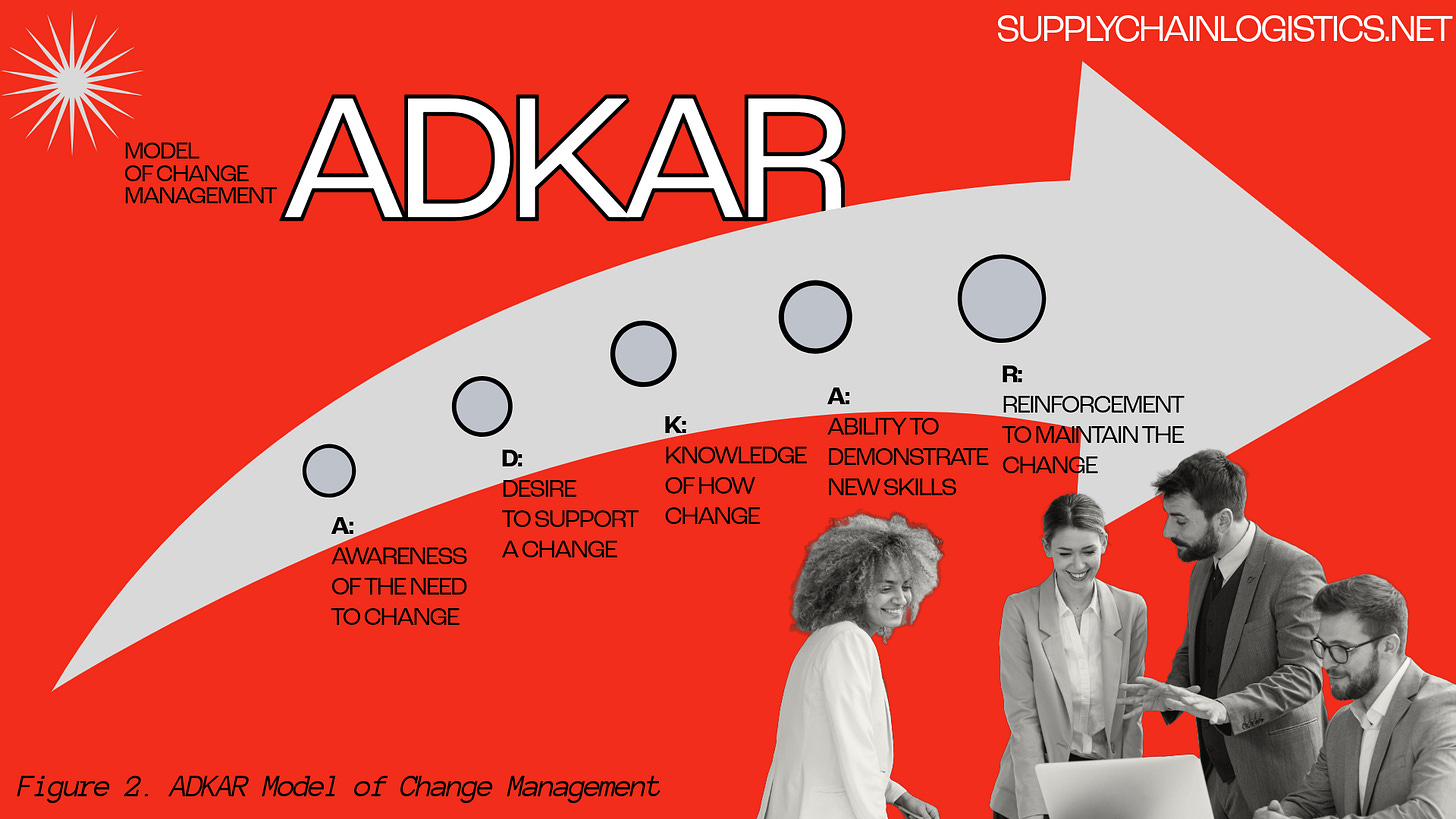

The ADKAR Model is a goal-oriented framework designed to manage the individual-level changes required for successful organizational transformation. Developed by Prosci founder Jeff Hiatt, the model emphasizes that organizational change is only successful when individuals successfully navigate their personal transitions. It is widely used because it focuses on five specific outcomes, making it easy to identify barriers and measure progress.

The ADKAR acronym outlines the five sequential goals an individual must achieve:

The ADKAR model is particularly effective as a measurement framework, with many practitioners using it to diagnose where resistance is occurring and create targeted action plans.

Part B: Kotter’s 8-Step Model for Change♟️

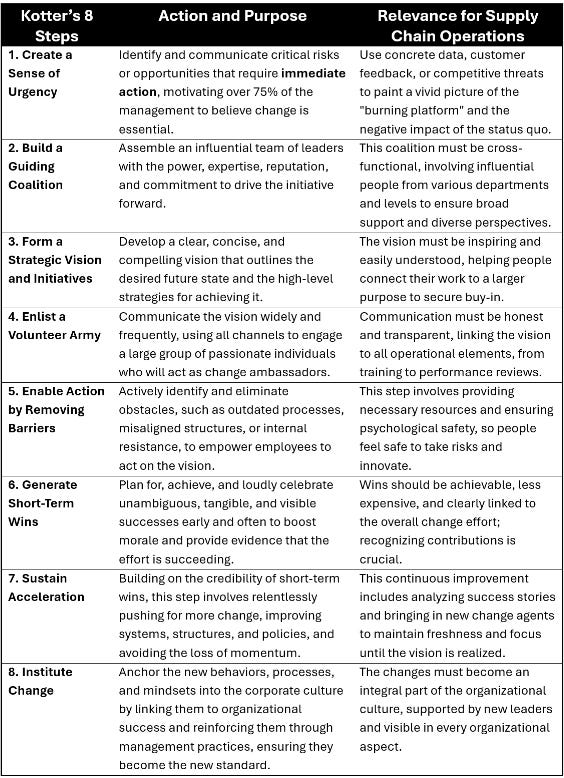

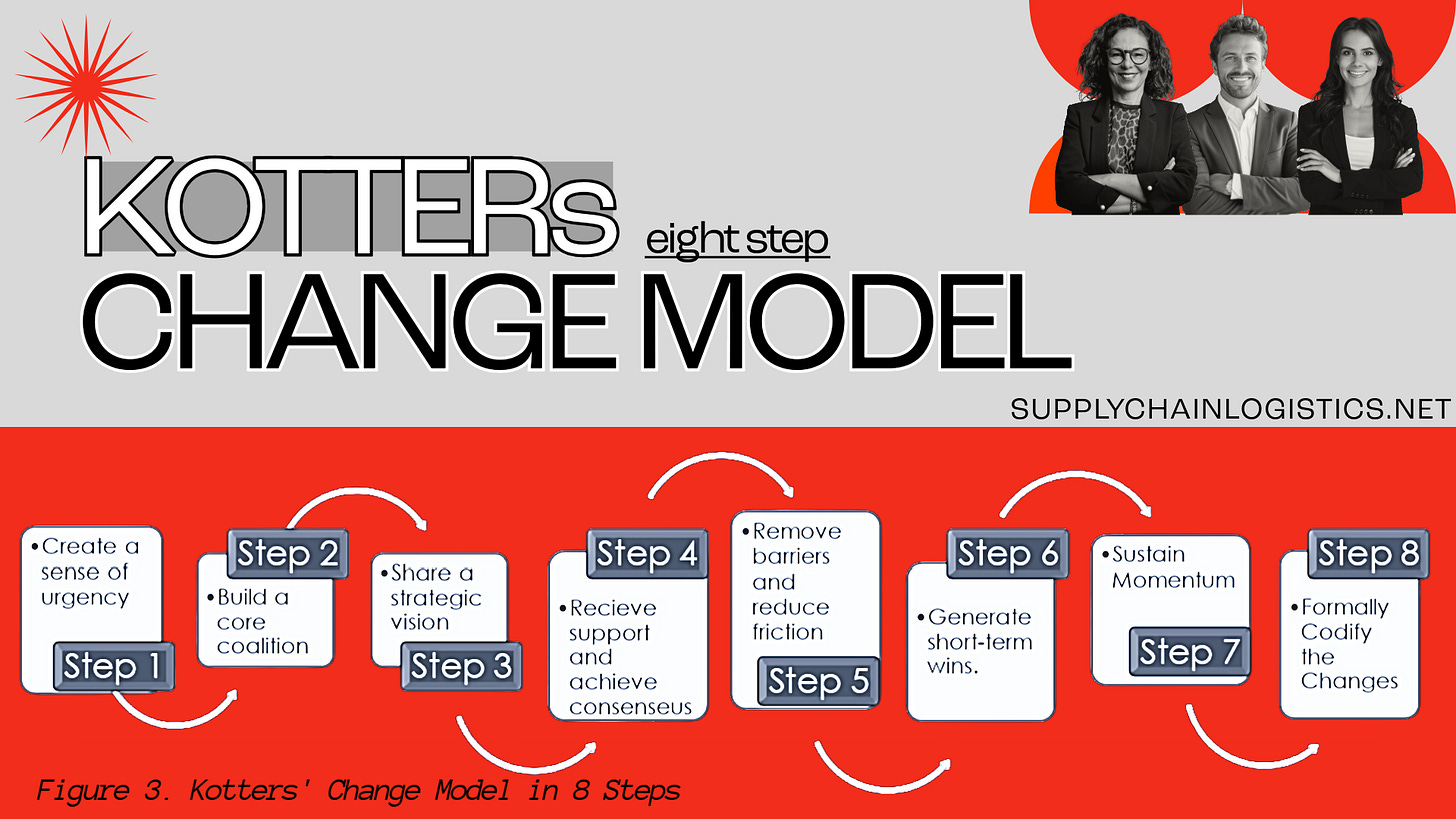

Dr. John Kotter’s 8-Step Process for Leading Change is a widely adopted, sequential methodology designed to systematically manage and accelerate large-scale organizational transformations.

Introduced in his 1996 book, Leading Change, the model is essentially a roadmap for a top-down approach, emphasizing the importance of strong leadership and a guiding structure to drive change into the corporate DNA.

The eight steps are typically grouped into phases (establishing the foundation, mobilizing the change, and making it stick) and must be followed in order to maintain momentum and credibility.

Kotter’s model provides a clear, step-by-step roadmap that emphasizes strong leadership and buy-in across the organization for the change initiative’s success.

SECTION 2:

This section includes a case example featuring a fictitious direct manufacturer of agricultural robotic automation products.

“Agri-RBA’s Organizational Change Challenge.”

Observe Change Management Models at Work: Kotters’ 8 Steps and the ADKAR Model of Change Management. A fictitious company “Agri-RBA” takes on the challenge of organizational change – is it too late to save the corporation from financial ruin?

Contents

Introduction

- Company: Agri-RBA Ltd.

- Key Issues

- Key Activities

- Current Status and Processes

Analysis & Recommendation

- A-1 Recommendation

- ADKAR Model of Change Management

- A-2 Recommendation

- 8 Kotter’s Model of Change Management

Conclusion

References & Resources

Introduction

Organization Overview:

- Company Name: “Agri-RBA Ltd.”

- Inception: Founded in 2015

- Description: Leading industrial autonomous robotics manufacturing company in Canada

- Location: Headquarters in Kitchener, ON

- Type: Direct manufacturing model with vertical integration

- Personnel: 500 production and supply chain staff

- Industry: Precision agricultural robotics for autonomous field operations

- Core Value: Customers as a long-term business partner

- Company Motto: “Build strong relationships, one customer at a time”

- Key Certifications: ISO 9001:2015 (Quality Management), Canadian Standards Association (CSA) safety standards compliance

The Issues:

After its initial launch and catapult to success, the company faced a stagnation and then a reversal of their former upward momentum. In 2019 it became clear that certain facts about the organization were contributing to the problem and the symptoms were showing up in the following metrics:

- Increasing product defect rates and quality complaints, particularly in electronic control systems and sensor calibration

- Rising number of CSA compliance violations and workplace safety board (WSIB) safety incidents on the production floor

- High employee turnover, specifically in production and quality control teams (47% annual turnover vs. industry average of 22%)

- Overall reduction in First Pass Yield (FPY) from 94% to 78% in the Canadian manufacturing department

- Growing customer dissatisfaction with product reliability, particularly field failure rates within warranty period

- Increasing warranty claims (up 180% over two years) and product returns due to defects

- Deteriorating Overall Equipment Effectiveness (OEE) despite high reported utilization rates

- Non-conformance reports (NCRs) being closed without proper root cause analysis

Related Activities:

- CEO’s Corporate Value: Stay close to the customers and maintain product excellence.

- Executive Action: Joining production managers on the manufacturing floor during shift changeovers and attending daily quality huddles and gemba walks.

- CEO Observation: Senior production supervisors and line managers were rushing through Standard Operating Procedures (SOPs), skipping documented quality checkpoints, and signing off on inspection reports without performing actual measurements. Critical torque specifications were being ignored, and statistical process control (SPC) charts showed evidence of data manipulation.

- CEO’s 1st Theory: Something is missing in production training and quality assurance protocols, particularly in understanding the consequences of process deviations.

- CEO’s Recommendation: Production staff need to be focused on product quality and customer satisfaction, not constantly worried about hitting cycle time targets and Overall Equipment Effectiveness (OEE) metrics to earn performance bonuses.

Current Status and Processes:

The Agri-RBA VP of Operations intends to release a new plan for training production staff.

New hires current training programs included:

- 2 weeks of classroom training covering:

- Workplace safety and WHMIS certification

- Introduction to ISO 9001 quality management system

- Basic lean manufacturing principles

- Reading technical drawings and work instructions

- 2 weeks of on-the-job training on the production floor covering:

- Equipment operation and setup procedures

- Quality inspection techniques and measurement tools (calipers, micrometers, CMM)

- Documentation requirements and traceability procedures

- Mentoring at the senior production supervisor’s direction, which was supposed to include:

- Advanced troubleshooting and process optimization

- When to stop the line for quality issues

- Proper escalation procedures for non-conformances

Actual Situation:

Senior supervisors were routinely cutting training short, having junior workers observe rather than practice, and teaching shortcuts that bypassed quality controls to maintain a faster production pace.

Analysis

Identifiable problems all link to the overall alignment with what the intended result is and what the company is experiencing. This is especially clear when the CEO observed that staff were not fully trained on skills that were necessary for success in production operations. When seeking to address the symptoms (observations), the corporation must look at the behaviors and the cause for those behaviors.

In this case, there is a mismatch between motivation for production staff and the intended focus on maintaining a customer’s satisfaction with the company overall. If the customer relationship and product quality are the intended focus of the corporation yet the reward always benefits production supervisors who maximize throughput, minimize downtime, and achieve high asset utilization rates, then the obvious action for earners is to prioritize immediate production volume without regard for quality control procedures, compliance requirements, or long-term product performance and customer safety.

The incentive structure explicitly rewarded:

- Machine uptime percentage (target: >85%)

- Units produced per shift (measured against standard time)

- Scrap rate minimization (which conversely acted to encourage hiding defects or reworking products off-record)

- Cycle time reduction (rewarding speed over accuracy)

Meanwhile, the following were either not measured or carried no financial incentive:

- First Pass Yield (FPY)

- Customer defect rates (PPM – parts per million)

- Training hours delivered to junior staff

- Time spent on root cause analysis and corrective actions

- Compliance audit scores

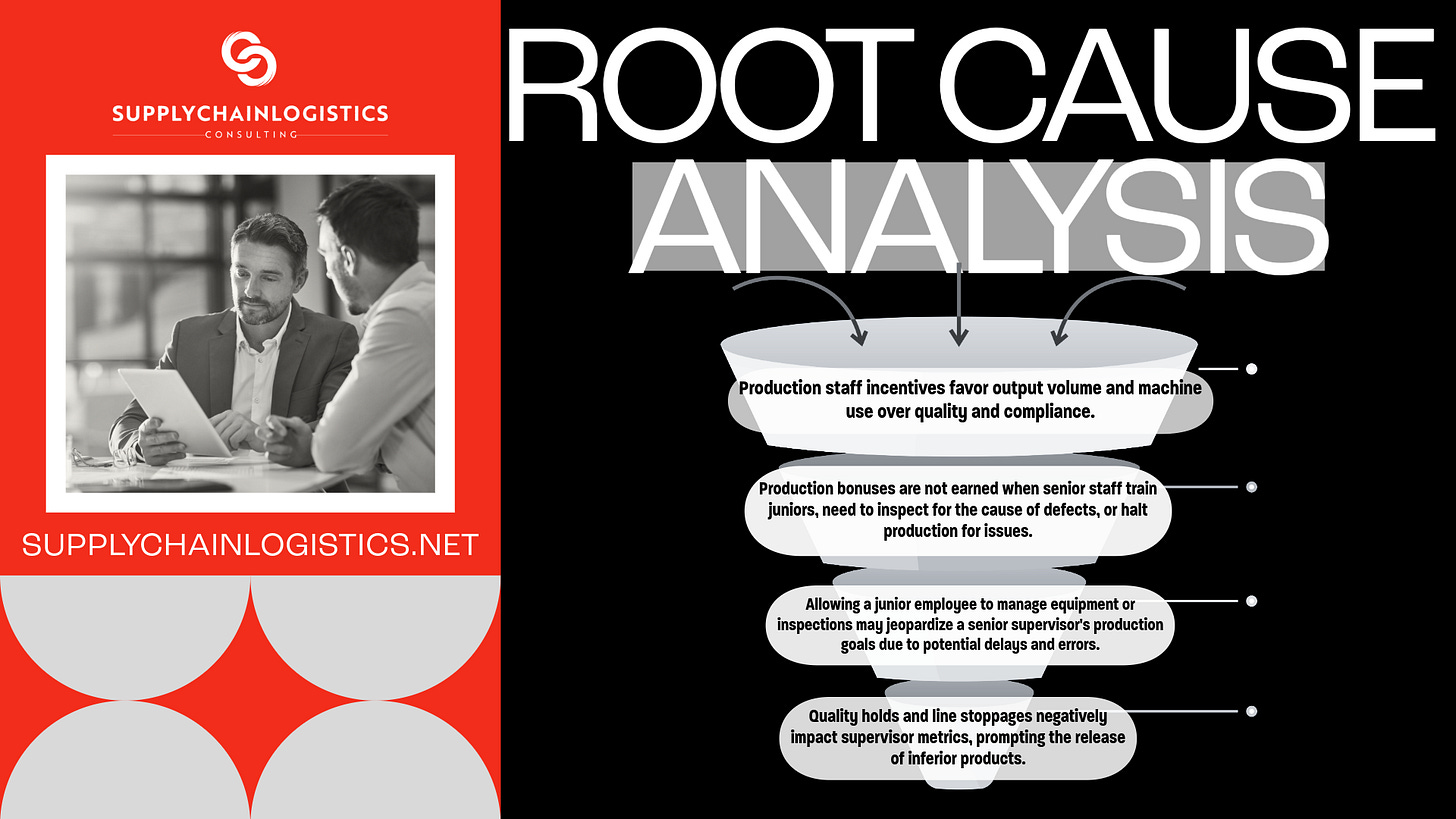

A quick root cause analysis review will trace back what is really happening by evaluating the formal structure of the system and the impacts on individuals or roles for a certain process.

1. Incentives and compensation for production staff are currently rewarding output volume, cycle time reduction, and machine utilization rates over quality outcomes and compliance adherence.

2. Production bonuses are not earned while senior staff are training junior employees on proper quality procedures, conducting root cause analysis, or stopping production to address systemic issues.

3. Allowing a junior employee to operate equipment or conduct in-process inspections jeopardizes production targets for a senior supervisor, particularly when the junior employee follows proper procedures that take more time.

4. Quality holds and line stoppages negatively impact supervisor performance metrics, creating incentive to release marginally acceptable products rather than addressing root causes.Figure 1. Simple Root Cause Analysis.

What employees can and cannot change themselves is important to acknowledge because it is an indication of what the corporation can do to get different results. Analysis of procedures can help to highlight behaviours that employees employ which may interfere with desired results and the ability to properly identify problems for early remediation.

Simple Root Cause Analysis:

- Incentives and compensation for production staff are currently rewarding output volume, cycle time reduction, and machine utilization rates over quality outcomes and compliance adherence.

- Production bonuses are not earned while senior staff are training junior employees on proper quality procedures, conducting root cause analysis, or stopping production to address systemic issues.

- Allowing a junior employee to operate equipment or conduct in-process inspections jeopardizes production targets for a senior supervisor, particularly when the junior employee follows proper procedures that take more time.

- Quality holds and line stoppages negatively impact supervisor performance metrics, creating incentive to release marginally acceptable products rather than addressing root causes.

This cycle clearly illustrates the gap between what is intended to be a positive learning experience for the new hire and what is being incentivized by the corporate system.

Without a reward of equal or adequate measure to ensure that new staff receive actual mentorship on quality protocols and compliance procedures, the individuals seeking their production bonuses will usually act in their own benefit. In fact, they risk losing earnings and falling out of favor with the company’s operations management for doing anything less. Senior supervisors reported that “stopping the line” to properly train someone or address a quality issue was seen as a “career-limiting move” that would be scrutinized in monthly performance reviews.

Downstream Effects:

- Junior production staff are not fully trained on quality procedures because it is not a priority to ensure they can do the job correctly—they learn the “fast way” not the “right way”

- New hires are explicitly told to “worry about speed first, quality will come later” which contradicts their classroom training

- Junior production staff enter a hostile environment where they compete with senior staff for production targets and fear being seen as “too slow” if they follow proper procedures

- Experienced quality inspectors leave due to frustration that their findings are ignored or they face pressure to “be more flexible” on acceptance criteria

- Corporate revenues slide as product quality deteriorates, warranty costs spike, and customers leave the company

- Brand reputation is at risk without anyone caring about the customer experience with product reliability and safety—several customers reported field failures during critical harvest seasons, causing significant financial losses

- Revenue decreases over time as repeat business is lost to competitors with better quality and compliance records

- Product sales drop as customers react to the worsening quality and increasing defect rates, with several major distributors issuing quality holds

- Regulatory risks increase as compliance violations accumulate—Transport Canada has flagged potential concerns with autonomous navigation safety systems

- Hidden factory costs increase as rework, warranty repairs, and customer service interventions consume resources without being properly tracked

- Erosion of quality culture as “good enough” becomes the unspoken standard and employees who raise concerns are labeled as “not team players”

A-1 Recommendation

A recommended course of action for the CEO and VP of Operations is to apply the ADKAR model of change management to the organizational issues and the company’s successful resolution of those problems.

ADKAR Model of Change Management

The ADKAR model of change management is explained in its name. A: Awareness of the need to change, D: Desire to support a change, A: Ability to apply new learnings, R: Reinforcement for sustained positive change.

A: Ability to apply new learnings,

D: Desire to support a change,

K: Knowledge of how to change,

A: Awareness of the need to change,

R: Reinforcement for sustained positive change.

Figure 2. ADKAR model for management of change.

When applied to Agri-RBA these stages will need to be customized to ensure they affect the people most impactful to the overall organization’s corporate culture where it matters the most. Specifically, the awareness of the need to change would not be of any use if it was clear to the finance team alone because most of the change in behaviors and systems or processes and people are in the production and quality assurance departments.

Awareness

Awareness needs to be communicated smartly and with precision to be effective and well understood by everyone. For production staff at Agri-RBA, this means sharing concrete data about the business impact: actual warranty costs, specific customer complaints with their emotional and financial impact, near-miss safety incidents, and the direct correlation between quality metrics and market share loss.

A true signal that the need to change has been communicated well is when the people who originally received this message can and will start to share the same information in depth with other people. This knowledge and awareness is the right kind of contagious behavior necessary to drive organizational motivation into the next stage, the desire for change. At Agri-RBA, this might look like production supervisors voluntarily discussing quality issues in shift handoffs or proactively sharing lessons learned from defects with their peers.

Desire

Desire must outweigh inertia and the inevitable resistance when challenges arise. Establishing a clear understanding of the problem by building adequate awareness will be the greatest source of success for this model.

“Desire must outweigh inertia and the inevitable resistance when challenges arise, establishing a clear understanding of the problem by building adequate awareness will be the greatest source of success for this model.”

Quote by Author.

Organizations underestimate their own inability to properly gauge the actual desire for change at a systemic level. The inertia of status-quo and power often being concentrated near supporters or beneficiaries of the current state is a large contributor to this immobility.

The next problem and most challenging to recognize from an outsider’s perspective, is the reluctance to talk about what is actually happening at the company by the people most affected. This is loosely related to the power structures already mentioned and can be another major symptom of rewards systems favoring the ‘good news bearers’ or ‘yes-people’ at the company. Employees who have already left the company are not around to ask either, though their very absence is an indication of a problem if it coincides with above normal rates of attrition as is the case with Agri-RBA.

Front line production staff or employees who have already left the company may not be open to sharing what they know about why things aren’t working well or where the issues are because they want their superiors to be happy with them, they may feel disloyal especially if they are new to the company, they may be afraid of the consequences or they may not believe that anything will change anyway because of unsuccessful attempts by management to ‘shake things up’ or to ‘make big changes’ which had only amounted to more work for the staff because of flawed and costly implementations.

Change efforts at an organizational level are always challenging and tax the people involved. Failed change efforts are often worse for employees who stay on with the company because they usually are tasked with more work and take on the burden when other staff leave, and their division finds itself short on human resources. At Agri-RBA, the production floor had already experienced two previous “quality initiatives” that began with enthusiasm but faded within weeks when the old incentive structures reasserted themselves.

Knowledge

Once awareness is established and desire is cultivated, employees need specific knowledge about how to operate differently. For Agri-RBA production staff, this means:

- Understanding new balanced scorecards that weight quality equally with productivity

- Learning proper use of statistical process control (SPC) tools and how to interpret control charts

- Training on root cause analysis methodologies (5 Whys, Fishbone diagrams, 8D problem solving)

- Clear protocols for when to stop production and how to escalate quality concerns without fear of reprisal

- Knowledge of how to conduct effective training sessions for junior staff

- Understanding the new documentation requirements that demonstrate training effectiveness

This knowledge phase requires significant investment in structured training programs, job aids, visual management systems on the floor, and accessible reference materials.

Ability

Ability is key. Unskilled and enthusiastic people will not drive the necessary growth for everyone at the organization and the goal for Agri-RBA is to bring the entire organization’s production team through to the ‘new normal’. This may include the ability to perform quality control procedures correctly using proper measurement techniques, the ability to interpret technical specifications and GD&T (Geometric Dimensioning and Tolerancing), and the ability to finance with capital the added requirements to enable new changes to take place, such as new quality management software systems, additional measurement equipment (CMMs, torque verification tools, environmental testing chambers), extra training and hiring new talent with complementary skills in quality assurance, metrology, and regulatory compliance.

People with the necessary skills and knowledge in key places for focused training and upskilling—these momentous changes can be made into active working processes for executable tasks and actions. If Agri-RBA does not have anyone with the correct skill set, they may need to recruit experienced quality engineers from automotive or aerospace sectors who bring mature quality cultures. If the existing trained senior production team carries a corporate culture with them that the organization wishes to shake off for something better, then there must be enough dilution to ensure they will be moved to change.

Pockets of self-serving employees with outdated attitudes who may have benefited from the old productivity-focused incentive structure must be broken apart and nourished under the new quality-focused business strategy. Else they may hoard knowledge about proper procedures and critical process parameters away from new hires which will be integral to bringing on a renewed brand identity as a company who cares about its customers’ safety and product reliability. Some senior supervisors may need to be moved to individual contributor roles if they cannot adapt to the new coaching and mentoring expectations.

Reinforcement

Reinforcement sounds harsh and perhaps it is being that it is somewhat akin to policing the atmosphere and actions of staff within the changed environment for any lapse or divergence. Not all mismatched actions will be from previous business practices at Agri-RBA. Some might be the result of changes which were implemented in process that have unforeseen results.

While the flexible and newly formed corporate production department normalizes the new attitudes, practical skills and processes of the improved quality-focused manufacturing model, each positive effect should be noted and celebrated. This includes:

- Recognizing employees who stop the line to address quality issues

- Celebrating improvements in First Pass Yield (FPY) and reductions in Non-Compliance Reports (NCRs)

- Sharing customer testimonials about improved product reliability

- Publicly acknowledging supervisors who invest time in training junior staff

- Tracking and reporting on leading indicators (process adherence, training hours completed, SPC compliance) rather than just lagging indicators (defect rates, warranty claims)

It is just as important to validate that this worked and all the effort to refine any new improved systematic processes are being rewarded with changes that will benefit everyone.

It does not hurt to remind the corporation staff of the reasons for the changes and to quantify any long-term positive response from their market or industry. Jointly acknowledging that the staff are better at what they do together supports the new structure of compensation for production supervisors, knowledge sharing and quality-oriented manufacturing.

The reinforcement phase also requires:

- Regular management review of quality metrics in monthly business reviews

- Continuous auditing of adherence to new procedures

- Adjustment of incentive structures to ensure they remain aligned with quality objectives

- Integration of quality performance into promotion criteria and annual performance reviews

A-2 Recommendation

The second school of thought follows another model for implementing Change Management. Although not wildly differentiated in most areas, there are certain recommended actions which will have greater emphasis that could lead Agri-RBA to experience greater success.

Kotter’s Model of Change Management

In the model developed to take a top-down approach as opposed to the bottom-up which is more distinct in the first of the two management models. The meaningful part of this difference is the amount of effort taken from ensuring buy-in or communication that establishes mutual agreement about the issues the company wishes to solve.

Kotter’s Change Model in 8 Steps.

Step 1

Create a sense of urgency

Step 2

Build a core coalition

Step 3

Share a strategic vision

Step 4

Receive support and achieve consensus

Step 5

Remove barriers and reduce friction

Step 6

Generate short-term wins.

Step 7

Sustain momentum

Step 8

Formally codify the changes

Figure 3. Kotter’s Change Model in 8 Steps.

In a top-down model like Kotter’s 8-Steps, less time is spent ‘listening’ to the organization and more time is spent creating the right environment with the right people in place to see the changes through to completion. Factors which might affect the decision to use Kotter’s model of change management could include the overall size of the organization and scope or complexity of the changes needed to make a new normal for the people within it.

Time is of the Essence

As Agri-RBA is limited to 500 staff overall, the scope of the change is not so great that time and resources couldn’t be devoted to ensuring adequate communication and awareness by all stakeholders in the proposed change. However, time is of the essence, and this could pressure the executive team to use a strategic deployment of information and leadership at every key intersection where the impact would be greatest, and change could result.

Inform and Explain

A sense of urgency can be created with timelines and sharing specific information about regulatory risks or liability exposure. For example, if there is a potential for major recalls (estimated at $2.3M per recalled unit based on field service costs, logistics, and brand damage), regulatory sanctions from Transport Canada or CSA, or legal liability from continued quality issues resulting in customer equipment failures during critical agricultural operations, then Agri-RBA has significant reason to believe that the change must be done quickly.

Additionally, the CEO can share market intelligence showing that two emerging competitors have achieved Six Sigma quality levels (3.4 defects per million opportunities) while Agri-RBA is operating closer to Three Sigma (66,807 DPMO), putting them at severe competitive disadvantage. The urgency is further reinforced by sharing that their largest distributor has issued a 90-day quality improvement ultimatum before switching to a competitor’s product line.

The choice is simple, either Agri-RBA adapts, or the company risks losing dissatisfied customers to competitors with better quality records and performance. They may not be given another opportunity to gain back customers lost while lagging on product quality.

Position the Super Supporters

Executives at Agri-RBA can more rapidly institute changes by placing change champions or subject matter experts at specific areas where their impact will be the greatest. These disruptors will serve as educators and guides towards what is needed and will have the necessary leadership or technical skills in quality management to manage unpredictable challenges that may arise.

For Agri-RBA, this might include:

- Appointing a Chief Quality Officer who reports directly to the CEO

- Placing ASQ-certified Quality Engineers (CQE) on each production line

- Embedding Lean Six Sigma Black Belts to facilitate DMAIC projects

- Assigning change champions who are respected production veterans and can speak credibly to staff about why quality matters.

Likely events where the subject matter supports are critical to mainitaining momentum towards change may include; staff shortages caused by people leaving who may not want to adopt a changed way of working, technical skills gaps in applied advanced analytics, statistical process control (SPC), or failure mode analysis (FMEA) that could result when disruptions happen.

Paint a Bright Picture

The communicative part of Kotter’s 8-Step change management model will spend less time on convincing people of the need to change, less time educating the corporation to the overall problems and nuances of all the issues, and more time on visionary activities such as explaining what benefits will be available in the future when things are done being changed.

For Agri-RBA, the vision might be articulated as: “We will become the most trusted name in agricultural robotics, known for products that perform flawlessly season after season. Our customers will choose us not just for our technology, but because they know we stand behind every unit with unwavering commitment to quality. Our employees will take pride in building products that help feed the world, and our production floor will be a place where craftsmanship and continuous improvement are celebrated daily.”

The vision must be so great that the corporate body will disregard what is challenging or difficult to get to the future status, which is another indication that this is a top-down model as less energy will be spent on educating staff and sharing perspectives.

Shake Up Power Dynamics

Consensus does not need to be one hundred percent to make the movement into Kotter’s next step. Again, this model is majority driven and leaves room for the early adopters and laggards alike. The fourth step ensures that the critical mass is attained, and momentum will carry the majority onto the actions for change. Executive leadership must facilitate momentum with actions to remove barriers such as access and communications boundaries, or delegated authority and empowering individuals.

At Agri-RBA, this means:

- Granting production workers authority to stop the line without supervisor approval (andon cord implementation)

- Removing bureaucratic approval chains for quality holds

- Providing direct access to engineering support for production floor issues

- Eliminating punitive measures for reporting defects or near-misses

- Restructuring the incentive system to include quality metrics with equal or greater weight than productivity metrics

These tactics loosen the rigidity of formal structures that organizations maintain for functional production on a day-to-day basis which will need to go through a series of adaptations and be reconfigured for new, more productive, quality-focused, and better aligned uses.

Stay the Course

As seen in cases where burnout becomes the precursor to failed change efforts. There are little things in disguise that can reveal themselves to actually be the big things. Making sure pivotal transition details are identified as a matter of importance, will help to avoid catastrophic reversals of an organizational change mid-way through. Kotter’s model of change management calls these ‘small wins’ and is correct to delineate a responsibility to deliberately create these experiences for staff and stakeholders of the change while it is in process.

Infuse Energy

New behaviours, skills and routines take energy to practice. Attitudes and corporate sentiment can be at a turning point already with the poor morale that year over year quality declines will inevitably bring about. This would be compounded by the burdensome self-made model of training and competitive culture of any production environment. More on point, the new methods will need enthusiasm and the top-down model attributes this responsibility to the executives.

Celebrate “Wins”

The small victories, recognition of little wins, and celebration of early milestones will be communicated the same way the change plan was given to the staff.

For Agri-RBA, small wins might include:

- First production line to achieve 95% First Pass Yield for a full week

- Successful completion of a root cause analysis that prevented recurring defects

- Zero safety incidents for a month

- Positive customer feedback on recent product deliveries

- Reduction in scrap rate by 15% in the first quarter

- Junior employee successfully completing a quality check that caught a critical defect

The staff will be looking towards leadership and longing for signals of progress because they have limited depth to their knowledge about the underlying reason and the original issues which led to the sudden dramatic change effort. Meaning that celebration points are absolutely critical for the participants’ morale and serve as a small reward for the staff’s hard work. Celebratory “wins” also act as an infusion of positivity which is great for teams with a strong vision and a long way still to go. This is as important, or even more of a priority than the efforts and actions needed to maintain progress throughout the change.

Formalize and Embed

Finally, Kotter’s plan is best for large enterprise because of the formal documentation required for the change. The importance placed on knowledge and structural integrity of new processes and systems in Kotter’s Change Management Model, tracks back to large groups, departments, or divisions. In those situations one-to-one conversation, cross-functional communication, and tacit knowledge are less likely to be reliable. Whereas the codified information management process in Kotter’s Model effectively grounds divergent beliefs from taking flight and provides a single source of truth maintained within the enterprise system itself.

For Agri-RBA, formalization includes:

- Updated ISO 9001 quality management system documentation reflecting new procedures

- Revised Standard Operating Procedures (SOPs) with explicit quality checkpoints

- Modified performance management system with balanced scorecard approach

- Integration of quality metrics into enterprise resource planning (ERP) system dashboards

- Formal training curriculum with competency verification requirements

- Updated job descriptions that explicitly include training and mentoring responsibilities

- Documented quality culture expectations in employee handbook and onboarding materials

Conclusion

In conclusion, the two change management models exist in unison, and both have potential to solve the problem at hand. Agri-RBA CEO and VP of Operations may wish to move quickly or take the time to formalize changes. This depends on the regulatory outlook, liability exposure, and the actual potential to grow beyond their current size quickly while maintaining quality standards.

In this case, the best course of action is to use the ADKAR model because staff at the organization will know the reason for change and will be prepared to share this knowledge with a rapidly expanding workforce. The flexibility of the ADKAR model is also advantageous and Agri-RBA executives will do well to check for continuous improvement opportunities along the way.

Quality management systems thrive on continuous improvement methodologies like Kaizen and PDCA (Plan-Do-Check-Act), making ADKAR’s iterative and inclusive approach particularly well-suited to embedding a culture of quality excellence throughout the organization. The model’s focus on individual change readiness also aligns well with ISO 9001’s emphasis on competence, awareness, and the engagement of people.

Furthermore, given that Agri-RBA’s workforce includes skilled tradespeople, technicians, and engineers who value craftsmanship and take pride in their work, the bottom-up engagement approach of ADKAR is more likely to create genuine buy-in and sustainable behavioral change than a purely top-down directive approach. The production floor culture in manufacturing environments responds better to “leading from within” rather than mandates from above, especially when dealing with matters of professional pride and workmanship quality.

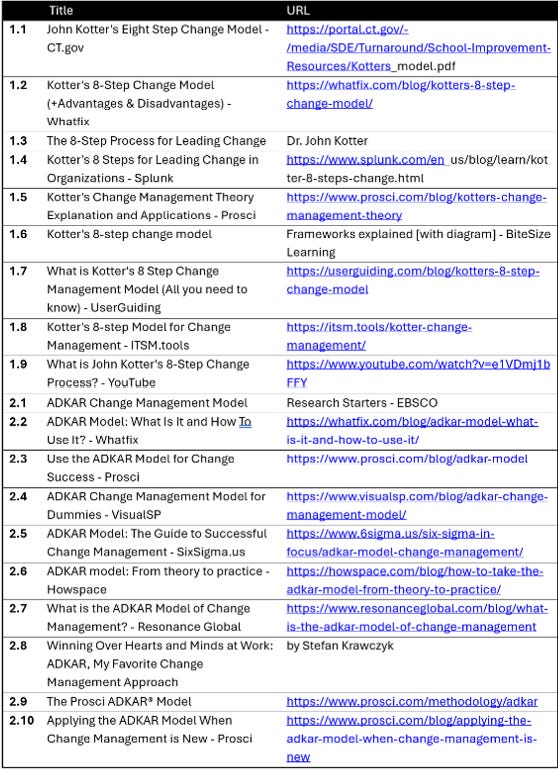

References

- Beatty, D. C. (2016). The Easy, Tough, and Hard Work of Managing Change. Queen’s University IRC (Industrial Relations Center).

- Bert Spector, N. U. (2013, 2010, 2007). Implementing Organizational Change, Theory Into Practice, Third Edition. Pearson.

Suggested Review:

- John Kotter’s Eight Step Change Model – CT.gov, https://portal.ct.gov/-/media/SDE/Turnaround/School-Improvement-Resources/Kotters_model.pdf

- Kotter’s 8-Step Change Model (+Advantages & Disadvantages) – Whatfix, https://whatfix.com/blog/kotters-8-step-change-model/

- The 8-Step Process for Leading Change, Dr. John Kotter https://www.kotterinc.com/methodology/8-steps/

- Kotter’s 8 Steps for Leading Change in Organizations – Splunk, https://www.splunk.com/en_us/blog/learn/kotter-8-steps-change.html

- Kotter’s Change Management Theory Explanation and Applications – Prosci, https://www.prosci.com/blog/kotters-change-management-theory

- Kotter’s 8-step change model, Frameworks explained [with diagram] – BiteSize Learning https://www.bitesizelearning.co.uk/resources/kotters-8-step-change-model

- What is Kotter’s 8 Step Change Management Model (All you need to know) – UserGuiding, https://userguiding.com/blog/kotters-8-step-change-model

- Kotter’s 8-step Model for Change Management – ITSM.tools, https://itsm.tools/kotter-change-management/

- What is John Kotter’s 8-Step Change Process? – YouTube ADKAR Change Management Model, Research Starters – EBSCO https://www.youtube.com/watch?v=e1VDmj1bFFY

- ADKAR Model: What Is It and How To Use It? – Whatfix, https://whatfix.com/blog/adkar-model-what-is-it-and-how-to-use-it/

- Use the ADKAR Model for Change Success – Prosci, https://www.prosci.com/blog/adkar-model

- ADKAR Change Management Model for Dummies – VisualSP, https://www.visualsp.com/blog/adkar-change-management-model/

- ADKAR Model: The Guide to Successful Change Management – SixSigma.us, https://www.6sigma.us/six-sigma-in-focus/adkar-model-change-management/

- ADKAR model: From theory to practice – Howspace, https://howspace.com/blog/how-to-take-the-adkar-model-from-theory-to-practice/

- What is the ADKAR Model of Change Management? – Resonance Global, https://www.resonanceglobal.com/blog/what-is-the-adkar-model-of-change-management

- Winning Over Hearts and Minds at Work: ADKAR, My Favorite Change Management Approach, by Stefan Krawczyk https://medium.com/@stefan.krawczyk/winning-over-hearts-and-minds-at-work-adkar-my-favorite-change-management-approach-d1077a06a18b

- The Prosci ADKAR® Model, https://www.prosci.com/methodology/adkar

- Applying the ADKAR Model When Change Management is New – Prosci, https://www.prosci.com/blog/applying-the-adkar-model-when-change-management-is-new

Are you looking for a professional and reliable professional to help you with your supply chain operations management? Do you want to optimize your supply chain performance and efficiency, enhance your customer service and satisfaction, and gain a competitive edge in the market? If so, you have come to the right place. Contact us today for a free consultation. We would love to hear from you and discuss how we can help with your supply chain operations management questions.

Take this opportunity to optimize your supply chain advantage.