Explore potential issues faced by firms utilizing a global production strategy in business. Understand various challenges and opportunities presented by these methods.

Business Planning: Global Production Strategies

An ingredients list for various Business Strategies.

This article explores potential issues faced by firms utilizing a global production strategy in business. The three major approaches to production a) centralized production, b) regional production, and c) fully vertically integrated production will review challenges and opportunities presented with each method. For businesses to thrive they must adopt an approach to resource management and choose the level of integration with suppliers.

Smart Business Moves: Aligning Strategy with Local Resources

For optimal results, consider aligning your business strategy with the resources and production capabilities of your operating region. From choosing the right location to sourcing materials, every decision impacts costs, capacity, and customer satisfaction. Keep these factors in mind for a successful venture.

Business planning requires a certain deliberate approach to key areas of development which will serve to shape the production and delivery of the finished product to a business’s end customer. For global producers working across international markets business planning decisions carry significant strategic importance for determining total quality and total risk profile of an organization.

Regionality of production, raw materials sourcing and product differentiation are key factors effecting the total cost and adaptability of businesses seeking output at optimal levels of production and simultaneously meeting market demand.

Factors in Decision Making

Important factors affecting each decision shown above are impacted by:

- Desired level of control over outputs,

- Budget available for development activities such as training and technical systems for supplier integration and customer orders,

- Amount of lead time to deliver goods from suppliers or to reach markets, and

- Importance of key inputs such as raw materials, skilled labour, or specialized equipment to produce the finished product.

Global Production Strategies

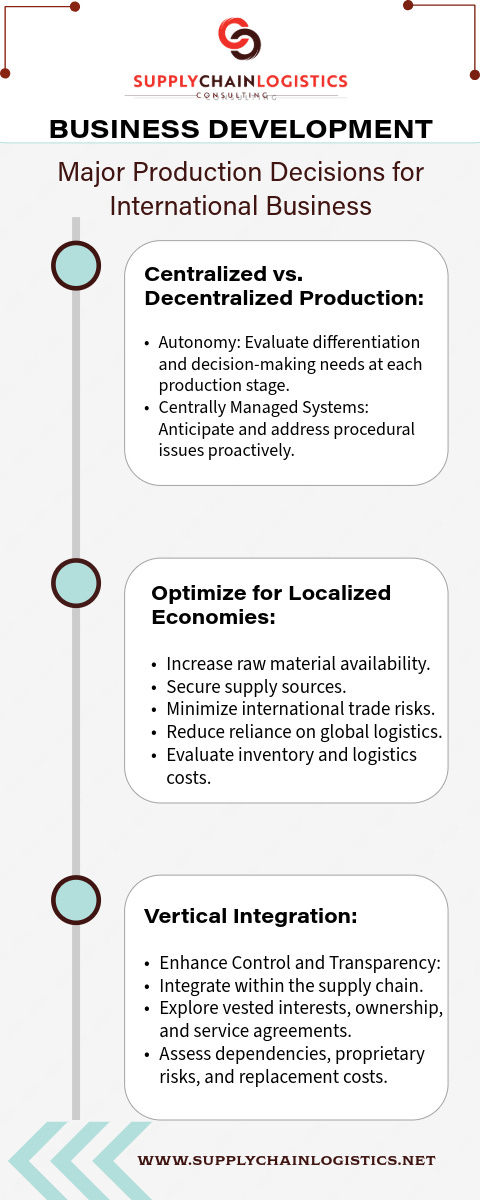

Major Production Decisions for International Business:

- Centralized vs. Decentralized Production:

- Autonomy matters: Consider the level of differentiation and decision-making power needed at each production stage.

- Centrally managed systems require foresight and proactive resolution of procedural issues.

Centralized production vs. decentralized production is a key factor for the level of differentiation in the production of goods and decision-making power required at various stages in production. More autonomy is needed when production challenges have broad range of potential solutions especially when there is an equal degree of uncertainty for their resolution. Developing processes and procedures to conduct business in a centrally managed system requires foresight and a dedicated approach to resolve procedural issues that will arise and doing so from a managerial perspective.

- Regional Production:

- Optimize for localized economies:

- Increase raw material availability.

- Secure supply sources.

- Minimize international trade risks.

- Reduce reliance on global logistics.

- Evaluate inventory and logistics costs alongside risk factors.

Regional production for localized economies to increase availability of raw goods and materials used in production and to secure sources of supply, reduce international trade risks, minimize inventory in-transit, and to decrease the reliance on global logistics for uninterrupted production. Inventory and logistics cost reduction and adequate risk evaluations will enable businesses to weigh the actual rewards of low-cost inputs from global suppliers with the potential for increased disruption or unpredictable events affecting their production inputs.

- Vertical Integration:

- Enhance control and transparency:

- Integrate along the supply chain.

- Explore vested interests, ownership, and service agreements.

- Assess dependencies, proprietary risks, and replacement costs.

Vertically integrated production and deeply integrated supplier systems to increase overall control and transparency of the upstream value chain. Methods of integrated production along a supply chain may include vested interests, partial ownership, highly developed service level agreements, or mergers and acquisitions of key parts, service, and material suppliers. Dependencies amidst producers vary with availability, proprietary risks, and the estimated cost of replacement for the same input from other sources making decisions for the level of integration with various suppliers highly relevant to strategy.

Key considerations: Companies in the international production planning process.

Integrated Economies:

When expanding internationally, consider regions with integrated economies. These areas facilitate business by removing restrictions on materials and labor movement. Sharing successes or failures within a more integrated economic market can be advantageous globally.

Corporations will select the geographic location of their production based on ease of doing business and integrated economies are a good place to look for expansion opportunities. Some nations have sought to remove restrictions for materials and labour to encourage movement freely between them and share the success or failure of a more integrated economic market at the global level.

Reinvestment vs. Divestment:

Financial profit distribution varies over time. Reducing leverage during economic uncertainty is prudent, as overextended obligations can impact agility. Companies may reinvest in capacity-building assets to seize market share or divest to reward shareholders. Balancing innovation, risk, and commitment is essential.

The redistribution of financial profits might change from year to year or over time as companies adjust to the desires of stakeholders and shareholders. Reducing leverage in economic conditions which may imply greater risk to the business is a wise decision as overstretching obligations will appear on the balance sheet or limit the ability to react well to disruptions affecting demand or supply of their product. Likewise, the company may see opportunity for growth of market share which would require a reinvestment in capacity building capital assets or allocation.

The need to innovate due to changes in technology and climate could demand higher allocation of resources for survival if the business wishes to secure itself a place in the markets of the future or they may divest to reward shareholders and to share business profits as commitments require which creates positive attraction for more investment.

Quality in Production:

Maintaining rigorous quality is paramount. International standards, such as ISO 9000, guide businesses in establishing protocols, audits, and performance benchmarks. Embrace continuous improvement cycles (Plan, Do, Check, Act) to exceed customer expectations and meet regulatory requirements.

Corporations must take a continuous improvement approach to maintain rigorous quality in the goods and services produced. Although international standards for quality involve certifications specific to industries, manufacturing is known for internationally for ISO 9000 as a basis for establishing documents, audits and testing protocols on which businesses can evaluate themselves and establish performance benchmarks with others. Cycles of Plan, Do, Check, Act, characterize the quality management approach and continuous improvement of businesses today, imperative to maintaining an upward spiral of quality assurance and high standards to meet or exceed expectations of customers and regulatory bodies.

Examples include:

• Total Quality Management Programs

• International Standards Organization (ISO) 9000 Certification.

• Six-Sigma and Lean Production

Human Resource Strategies:

Prepare managers for successful international ventures. Cultural, environmental, and language training are crucial. Upskilling regional employees aligns talent with business needs. Safety and health standards may differ; provide personal protective equipment to uphold quality. Engage local resources for seamless integration and future supply availability.

Human resources and occupational health teams advise on insurance, labor standards, and reporting. Wellness programs foster healthy communities, ensuring ongoing production.

Managers will need training and preparation to make international business ventures a success and effective strategies include cultural, environmental and language training. The regional employees may require upskilling and corporate orientations to align their abilities with the companies need for talent and this extends to safety and health standards which might differ from local norms.

Clothing, equipment and making provisions to supply employees with personal protective equipment can be up to the employer to provide if they wish to uphold certain standards and reduce incidents from non-compliant or low quality substitutions purchased by employees. Effectively using a human resource department and purchasing to supply from local providers might be an adept way to integrate more fully with the local economy and increase future availability for the same standard of supply.

Human resources and occupational health and safety teams to advise the corporation about specific insurance, labour standards and regional reporting requirements that need to be observed. The same goes for encouraging participation in wellness programs to develop workers communities with healthy people to help secure the availability of labor and ongoing production.

Seek Alignment with Regional Resources and Capabilities

In the pursuit of operational excellence, companies should strategically align their decisions with the unique resources and production capabilities of the region where they plan to operate. This deliberate evaluation encompasses various aspects, from selecting the optimal geographic location and designing efficient operational facilities to optimizing production processes and sourcing material inputs.

For the expansion of business operations into new territory, each decision holds strategic significance, directly influencing cost management, capacity utilization, customer satisfaction, and overall financial performance.

In Conclusion:

Navigating International Business Ventures Is Complex. Not Impossible.

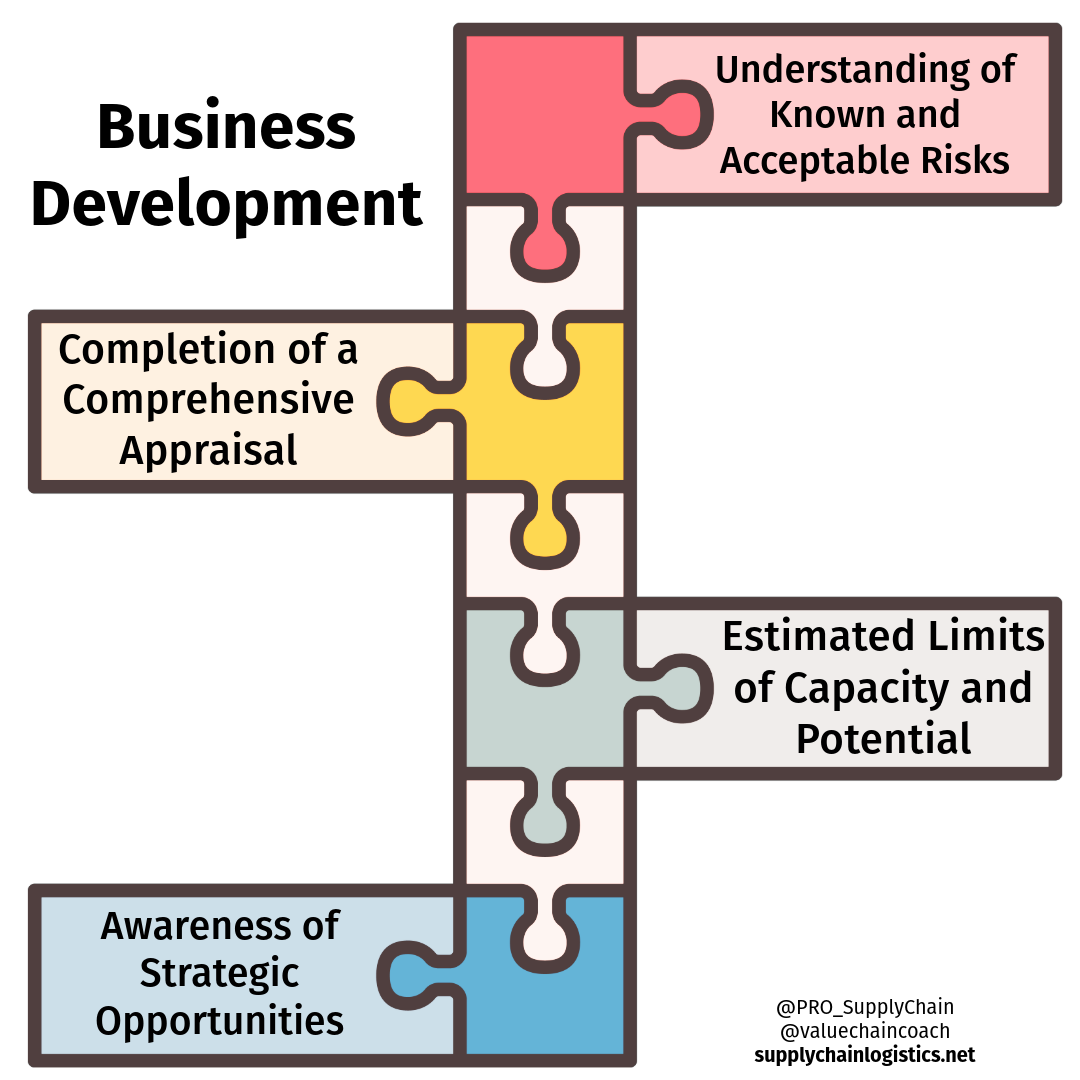

The international business plan offers opportunities to explore the risk appetite of ventures, either established or starting up. Regardless of the level of success in domestic markets each are well-advised to take an open and honest appraisal of their current capacity, potential environments, and ability to withstand any unforeseen challenges or achieve greater success with new opportunities.

- Exploring Risk Appetite: The international business plan provides a framework for assessing the risk tolerance of both established and startup ventures. It encourages businesses to evaluate their readiness to enter new markets.

- Comprehensive Appraisal: Success in domestic markets doesn’t guarantee international success. Companies must conduct a thorough and honest evaluation of their current capabilities and potential challenges in new environments.

- Capacity and Potential: Understanding one’s capacity to handle unforeseen challenges and seize new opportunities is crucial. This involves assessing resources, market conditions, and strategic fit.

- Strategic Opportunities: The plan highlights the importance of identifying and leveraging new opportunities for growth and success in international markets.

By following these guidelines, businesses can better navigate the complexities of international expansion and position themselves for sustainable growth.

At Supply Chain Logistics Consulting our mandate is to improve the way things are done and we would be happy to hear from you.

Visit Supply Chain Logistics Consulting online and subscribe on all our channels.