Back-to-Basics: “Purchase Order Types”

The Five Minute Explanations in our Back to Basics series breaks down similar concepts in quick comparisons that are designed to clarify concepts quickly.

Members can follow topics, access premium resources, get promotional discounts like free downloadable infographics, and anyone can request customized materials. *Learn more here.*

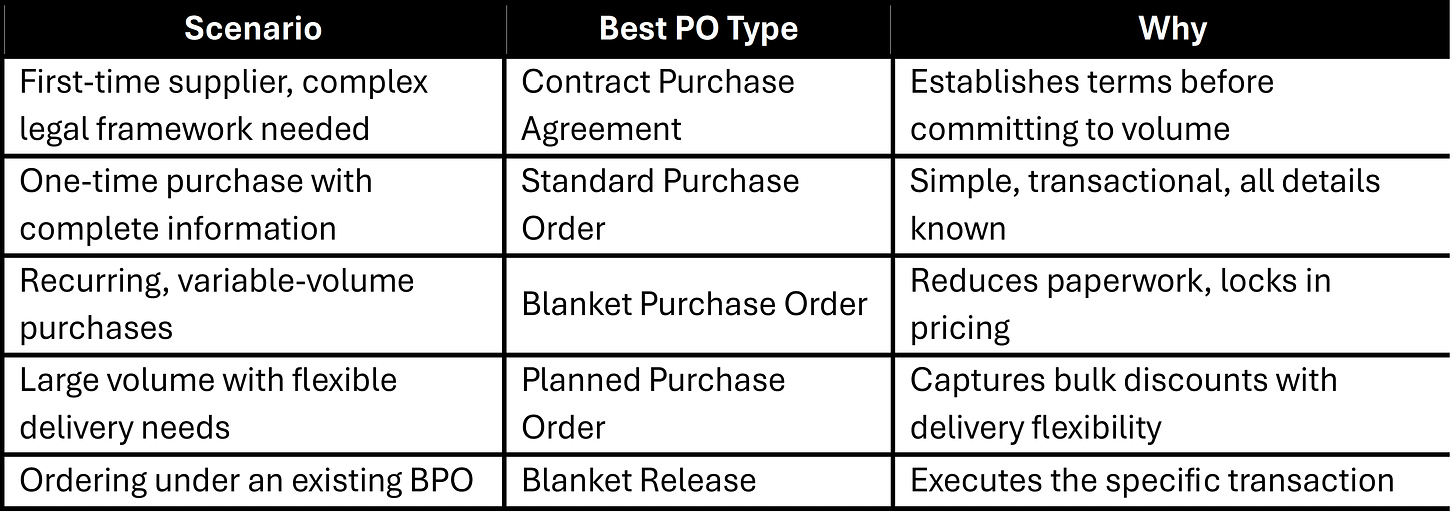

Get to Know these Essential Purchasing Agreements:

Effective procurement begins with selecting the right purchasing agreement for your specific business need. When leaders understand the different types of purchase agreements available—commonly referred to as purchase orders—they gain the flexibility to respond to market changes while maintaining cost control and supply chain stability.

Each purchase order type serves a distinct strategic purpose, offering different levels of operational flexibility and financial security. This guide takes business leaders through several core purchasing agreements used in modern supply chains, helping you to build a more resilient and adaptable procurement strategy.

Get whitepapers, ebooklets, and our infographics, or order your own from our Buy-Me-A-Coffee page. Members receive exclusive unlimited access to limited offers. Learn more about our new programs, monthly consulting, and latest updates at supplychainlogistics.net or our monthly newsletter -> SUBSCRIBE HERE

“Contract Purchase Agreement” (PA)

A legal agreement that only need contain terms and conditions governing purchases from the supplier without specifying order details.

“Contract Purchase Agreement” (PA)

A legal agreement that only need contain terms and conditions governing purchases from the supplier without specifying order details.

Deeper Dive:

Purchase Agreement (PA) – Establishing the Framework

What It Is: A Contract Purchase Agreement creates the foundational legal structure between a buyer and supplier without committing to specific quantities or delivery dates. Think of it as the rulebook that governs all future transactions between the two parties.

When to Use It: The PA works best when you want to lock in favorable terms, pricing structures, and performance standards before you know exactly what you’ll order. This approach saves substantial time and legal costs on subsequent transactions because the complex legal groundwork is already complete.

What Gets Covered: Your PA establishes payment terms (Net 30, Net 60, etc.), quality standards, inspection procedures, liability frameworks, intellectual property protections, and performance guarantees. The document creates certainty around the “how” and “what if” before addressing the “what” and “when.”

Real-World Examples:

-

Electronics Manufacturing: A component distributor signs a PA with a specialized supplier that defines acceptable quality thresholds, handling requirements for sensitive parts, and liability terms for defective inventory—but the distributor doesn’t commit to purchasing 50,000 resistors until demand forecasting confirms the need.

-

Professional Services: A consulting firm establishes a PA with a cloud-based project management platform. The agreement locks in data security standards, uptime guarantees (99.5% availability), user license terms, and support response times—allowing the firm to quickly add user seats as new employees join without renegotiating every detail.

-

Healthcare Supply: A hospital system uses a PA with a medical equipment supplier to establish sterilization protocols, replacement timelines, and warranty terms before confirming actual equipment purchases.

“Standard Purchase Order” (SPO)

The quantities, delivery schedule, and price, are known, as are the terms and conditions, all get included in the legal contract to purchase the order.

“Standard Purchase Order” (SPO)

The quantities, delivery schedule, and price, are known, as are the terms and conditions, all get included in the legal contract to purchase the order.

Deeper Dive:

Standard Purchase Order (SPO) – The Classic Transactional Purchase

What It Is: A Standard Purchase Order is a straightforward legal commitment to purchase a specific quantity of goods or services at an agreed-upon price with a defined delivery date. It’s the most common purchase order type because it works for one-off, clearly defined transactions.

When to Use It: Deploy SPOs when you have complete information upfront: you know what you need, how much it costs, when you need it, and the supplier can commit to those terms. This is the workhorse of procurement for non-recurring or periodic purchases.

What Gets Specified: Your SPO documents the exact product or service, quantities, unit pricing, total contract value, delivery deadline, and any special conditions or acceptance criteria.d.

Real-World Examples:

-

Retail Seasonal Buying: A boutique clothing store needs 200 units of a specific dress style before the fall season launch. The SPO specifies the exact style number, color, size distribution, unit cost ($45), total order value ($9,000), and warehouse delivery date (August 15). Everything is locked in because the buyer has already negotiated with merchandising on inventory needs.

-

Equipment Procurement: A manufacturing operations manager purchases a new forklift for the warehouse. The SPO captures the model number, lift capacity, attachments included, negotiated price, delivery and installation date, and references the supplier’s 2-year warranty coverage.

-

Event-Based Purchasing: A conference organizer places an SPO with a catering company: 500 attendees, plated lunch service, $28 per person, delivery by noon on June 15th, with final headcount confirmation 10 days prior.

“Blanket Purchase Order” (BPO)

A legal agreement typically for long term supply of specific goods or services of an unknown quantity and no scheduled delivery, prices can be negotiated in advance. Also known as a standing order or blanket purchase agreement.

“Blanket Purchase Order” (BPO)

A legal agreement typically for long term supply of specific goods or services of an unknown quantity and no scheduled delivery, prices can be negotiated in advance. Also known as a standing order or blanket purchase agreement.

Deeper Dive:

Blanket Purchase Order (BPO) – Long-Term Supply Agreements

What It Is: A Blanket Purchase Order establishes a supplier relationship for recurring, ongoing purchases where the total quantity and delivery schedule may shift over time, but pricing is fixed or has been pre-negotiated. It’s also called a standing order or blanket purchase agreement.

When to Use It: BPOs excel for repetitive purchasing needs where you can’t predict exact timing or quantities but want price certainty and operational efficiency. They eliminate the administrative burden of creating a new purchase order every time you need something.

Why They Matter: Rather than issuing individual purchase orders 50 times a year, you establish one agreement that covers the entire relationship, often with a maximum dollar commitment. This streamlines workflows, secures volume discounts, and maintains consistent pricing throughout the contract term.

Real-World Examples:

-

Manufacturing Maintenance: A food processing plant uses standard fasteners, lubricants, and replacement seals continuously but in unpredictable quantities. A BPO is established with a local maintenance distributor for a one-year term with a $75,000 maximum spend. The supplier extends a 15% volume discount across all line items. The plant’s maintenance team orders small batches weekly as needed—sometimes $200, sometimes $1,200—all under this single agreement without approval delays.

-

Corporate Office Supplies: A growing technology company establishes a 18-month BPO with an office supply vendor for all paper, printer cartridges, desk accessories, and stationery. The agreement fixes prices 12% below retail despite varying monthly orders. Finance can forecast the monthly burn rate but departments maintain flexibility to order based on actual consumption.

-

Hospitality Inventory: A hotel chain creates a BPO with a linen supplier covering all pillowcases, sheets, and towels. With 25 properties, volumes fluctuate seasonally and due to occupancy rates, but the BPO maintains consistent per-unit pricing across the entire portfolio.

“Planned Purchase Order” (PPO)

The purchased quantities and pricing are known and in the agreement with a supplier where terms are set in a contract purchase order.

“Planned Purchase Order” (PPO)

The purchased quantities and pricing are known and in the agreement with a supplier where terms are set in a contract purchase order.

Deeper Dive:

Planned Purchase Order (PPO) – Balancing Commitment with Flexibility

What It Is: A Planned Purchase Order commits to a specific total quantity and price but allows flexible delivery scheduling. You’re locking in volume and cost but retaining control over the timing and staging of deliveries.

When to Use It: PPOs fit situations where you want bulk discounts (requiring volume commitment), but warehousing constraints, production schedules, or cash flow management requires spacing out deliveries over time.

The Strategic Advantage: You capture supplier pricing benefits equivalent to buying everything upfront, but you manage inventory carrying costs and cash outflows by receiving goods in planned phases.

Real-World Examples:

-

Manufacturing with Phased Production: A furniture manufacturer secures a major retail contract requiring 12,000 yards of upholstery fabric over 12 months. The supplier quotes $18/yard for the full quantity but $24/yard for monthly purchases. A PPO commits to all 12,000 yards at $18/yard, yet the delivery schedule is set for 1,000-yard shipments on the first of each month. This allows the furniture plant to optimize warehouse space while the supplier gains revenue certainty.

-

Publishing and Retail: A bookstore chain anticipates selling 40,000 copies of a highly publicized autobiography over six months. The publisher offers $12/copy for the full commitment but $14.50/copy for monthly orders. The PPO locks in the lower price for all 40,000 books also structures deliveries in three waves: 15,000 copies two weeks pre-launch, 18,000 at launch, and 7,000 for post-launch restocking. This manages shelf space and demand variability while securing the discount.

-

Seasonal Food Service: A large restaurant group commits to 50,000 pounds of tomatoes for summer menu items at $0.85/lb. A PPO with a regional produce supplier guarantees that price yet allows weekly deliveries of 2,000-5,000 pounds depending on restaurant demand, ensuring freshness while maintaining cost predictability.

“Blanket Release”

A record that, when issued, authorizes the use of allocated funds to execute a purchase against a blanket purchase order (BPO) and includes all details of quantity, delivery schedule, and price, that meet conditions to fulfill the order.

“Blanket Release”

A record that, when issued, authorizes the use of allocated funds to execute a purchase against a blanket purchase order (BPO) and includes all details of quantity, delivery schedule, and price, that meet conditions to fulfill the order.

Deeper Dive:

Blanket Release – The Execution Document

What It Is: A Blanket Release is the action document that executes a specific purchase transaction within an existing Blanket Purchase Order. It’s the authorization that says, “Now, under the framework we established, I’m requesting ‘N’ quantity, at this price, for delivery on this date.”

The Relationship: Think of a BPO as the playbook and the Blanket Release as calling a specific play. The BPO establishes the rules and negotiated terms; the Release executes one specific transaction within those rules.

What Gets Documented: Each Blanket Release includes: part or service number, specific quantity needed, agreed-upon price, delivery location, required delivery date, and any order-specific conditions (e.g., “deliver between 2-4 PM”).

Real-World Examples:

-

Maintenance Operations: A manufacturing facility operates under a year-long BPO with a hydraulics supplier covering emergency repair parts at pre-negotiated pricing. When the production line’s main pump fails, the maintenance technician issues a Blanket Release requesting one replacement pump (part XYZ-4400), at $3,200 (per the BPO rate), for next-day delivery to the loading dock. The order is processed immediately without renegotiating price or terms.

-

Warehouse Replenishment: A 3PL logistics company has a BPO with a packaging materials supplier for pallet wrap, banding, and dunnage at fixed pricing. When the warehouse manager’s inventory system flags low pallet wrap stock, they issue a Blanket Release for 50 rolls, scheduled delivery Thursday morning. Multiple Releases flow throughout the year under the single BPO, each triggering a specific shipment.

-

Healthcare Consumables: A hospital has a BPO with a medical supply company for gloves, syringes, and bandages. When the hospitals Operating Room manager needs 10 boxes of sterile gloves for an emergency surgery, a Blanket Release authorizes the purchase at the pre-agreed price and requests same-day courier delivery.

Supply Chain Strategy Insights

Different business situations demand different purchasing agreement types.

By understanding when each purchase order type creates the most value—whether that’s securing legal certainty, reducing administrative overhead, capturing volume discounts, or maintaining operational flexibility—you build a more resilient and cost-effective procurement function. The most effective supply chain leaders don’t rely on a single approach; they select the right tool for each purchasing decision.

—

We’re grateful for those who donate on buy-me-a-coffee to show their appreciation plus those who simply share and enjoy our content! Thank-you.

Subscribe | Join Free | Memberships

✔️ LIKE, SHARE, & INTERACT WITH OUR CONTENT WHEN YOU SEE IT ✔️